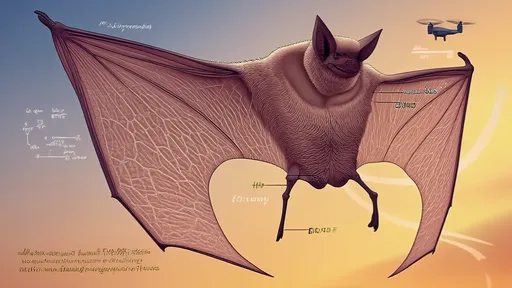

The marvel of bat flight has long captivated biologists and engineers alike. Unlike birds or insects, bats achieve powered flight through a unique anatomical adaptation: elongated finger bones supporting a thin, flexible membrane. This evolutionary innovation, refined over 50 million years, represents one of nature’s most extraordinary examples of biomechanical efficiency. Recent advances in materials science and aerodynamics have allowed researchers to reverse-engineer this biological blueprint, unlocking groundbreaking applications in flexible-wing robotics and adaptive aerospace structures.

At the core of bat flight mechanics lies the chiropteran wing membrane, or patagium. This stretchable skin spans between dramatically extended digits—essentially turning the entire forelimb into an airfoil. The fourth digit (equivalent to our ring finger) often exceeds the animal’s body length, creating a skeletal framework that can adjust wing curvature mid-flight. Engineers now recognize this design as nature’s solution to conflicting demands: maintaining structural integrity while allowing instantaneous shape-shifting for complex maneuvers.

Material scientists have made significant breakthroughs in replicating the patagium’s dual properties of toughness and elasticity. The natural membrane combines collagen fibers arranged in a cross-hatched pattern with elastin proteins, enabling it to withstand tremendous aerodynamic forces without tearing. Synthetic versions using graphene-infused polymer matrices now demonstrate similar characteristics, with some laboratory prototypes achieving 300% stretchability while maintaining the tensile strength of aircraft-grade aluminum. These bio-inspired materials are being tested in morphing drone wings that can alter their surface area by up to 40% during flight.

The finger bone extension mechanism presents another engineering challenge beautifully solved by evolution. Bat phalanges contain a unique honeycomb microstructure that minimizes weight while maximizing bending resistance. Researchers at MIT’s Center for Biomechanical Engineering have 3D-printed titanium replicas of this spongy bone architecture, creating support struts for experimental aircraft that weigh 60% less than conventional aluminum spars. When combined with the synthetic membrane, these structures form wings that can dynamically adjust their camber—the curvature critical for lift generation—through simple tendon-like actuators rather than complex hydraulic systems.

Perhaps the most revolutionary application emerges in micro-aerial vehicles (MAVs). Traditional fixed-wing drones struggle with tight spaces and gusty conditions where bats excel. A team at Stanford’s Bio-Inspired Research Lab recently demonstrated a palm-sized drone featuring finger-like carbon fiber ribs covered with a silicone-based artificial patagium. During tests, the device performed unprecedented mid-air flips and rapid decelerations by folding individual “digits,” mimicking how bats navigate dense foliage. Such capabilities could transform search-and-rescue operations in collapsed buildings or wildfire zones.

Beyond aviation, the principles of bat wing design are influencing next-generation wearable technology. Flexible solar panels modeled after the patagium’s strain distribution patterns maintain efficiency when bent around curved surfaces. Biomedical engineers are developing stretchable electronic skins for prosthetics that incorporate the membrane’s sensory network—bats have touch receptors across their wings that provide real-time airflow data. Early prototypes allow amputees to “feel” wind direction through their artificial limbs, enhancing balance and mobility.

The environmental implications of these innovations are equally profound. Unlike conventional aircraft materials that require energy-intensive manufacturing, bio-inspired membranes can be produced at room temperature using biodegradable polymers. Airbus has partnered with the Bat Conservation Trust to develop wing coatings that reduce drag by emulating the microscopic texture of bat skin, potentially cutting fuel consumption in commercial aviation by 8-12%. Meanwhile, wildlife researchers are using bat-wing-inspired acoustic sensors to monitor endangered species, as the membrane’s vibration patterns naturally amplify certain frequencies.

As research progresses, scientists continue uncovering deeper layers of sophistication in chiropteran flight systems. Recent studies reveal that bats actively stiffen their wing membranes using muscular control—a feature now being incorporated into “smart” materials that change rigidity on demand. Other teams are studying how blood vessels within the patagium regulate temperature during flight, inspiring self-cooling systems for high-performance electronics. Each discovery reinforces how much remains to be learned from these nocturnal aviators.

From Leonardo da Vinci’s ornithopter sketches to modern aerospace laboratories, humanity’s quest for flight has consistently drawn inspiration from nature. The bat’s elongated finger wing represents perhaps the most sophisticated biological flight apparatus yet decoded. As engineers refine their biomimetic designs, we edge closer to achieving what evolution perfected eons ago: effortless, adaptable, and astonishingly efficient flight. The next generation of aircraft may not resemble bats in appearance, but their wings will undoubtedly carry the legacy of these remarkable creatures.

By /Jun 10, 2025

By /Jun 10, 2025

By /Jun 10, 2025

By /Jun 10, 2025

By /Jun 10, 2025

By /Jun 10, 2025

By /Jun 10, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025